Assembly technology at the highest level

Perfectly brought togetherThe manufacture of hybrid assemblies from different functional and production parts requires a clear and precise design. Assembly processes, coupled with the simultaneous monitoring of individual steps, are both a technical challenge and one of our greatest strengths. This is how we turn components into a finished product for our customers.

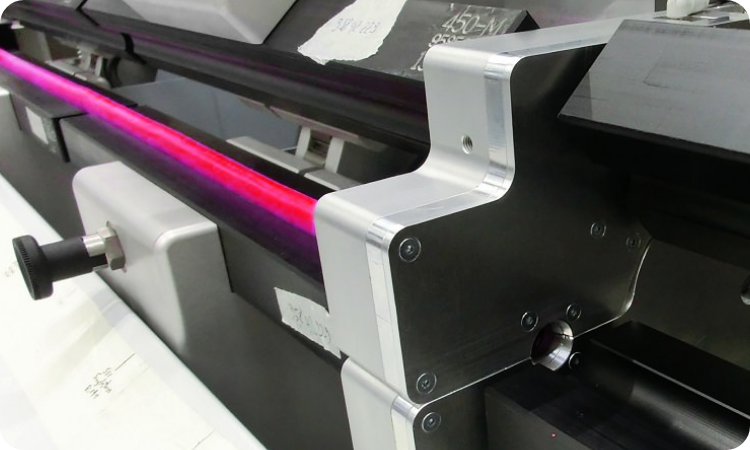

Hybrid cables

Hybrid technology is omnipresent in the automotive industry. Here too, we have supported our customers professionally right from the start: We design semi-automatic systems for fitting aramid, silicone, crash and heat protection conduits as well as grommets on high-voltage cables.

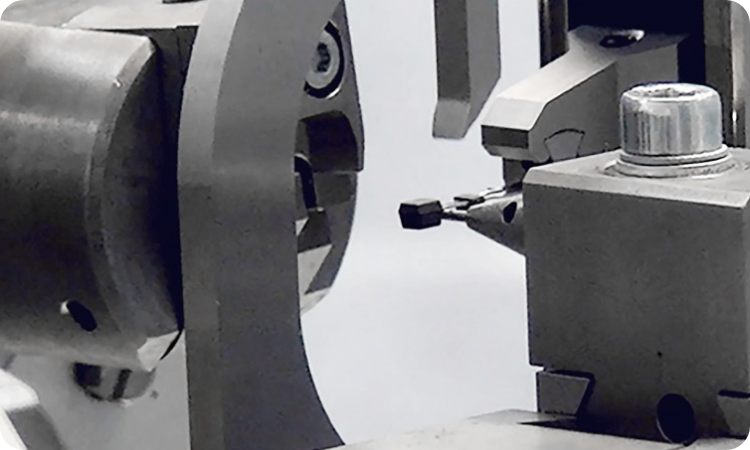

Punching and bending technology

Our stamping and forming technology shapes a wide variety of metal components according to individual customer requirements. The result is precise custom-made products that are used in numerous industries and systems.

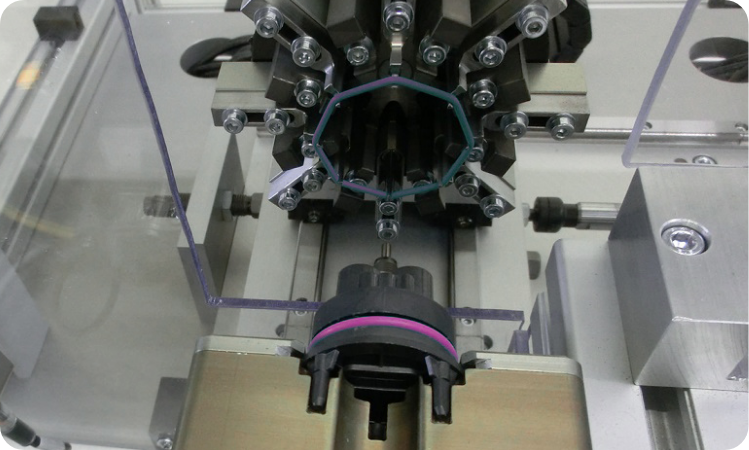

Fully automatic assembly of components

With our assembly systems, we enable electronic components and hybrid assemblies to be produced in customized automated processes. Our systems are characterized by shape and position tolerances as well as process-reliable dimensional accuracy in a compact design. Fully automatic feeding systems as well as functional/final testing and packaging technology round off the finished overall solutions.

Fully automatic processing of components

Whether drilling, milling, turning, cutting or grinding, the machining of components is a task that is used in our automation systems.

We are here for you!

Do you have any questions or requests?