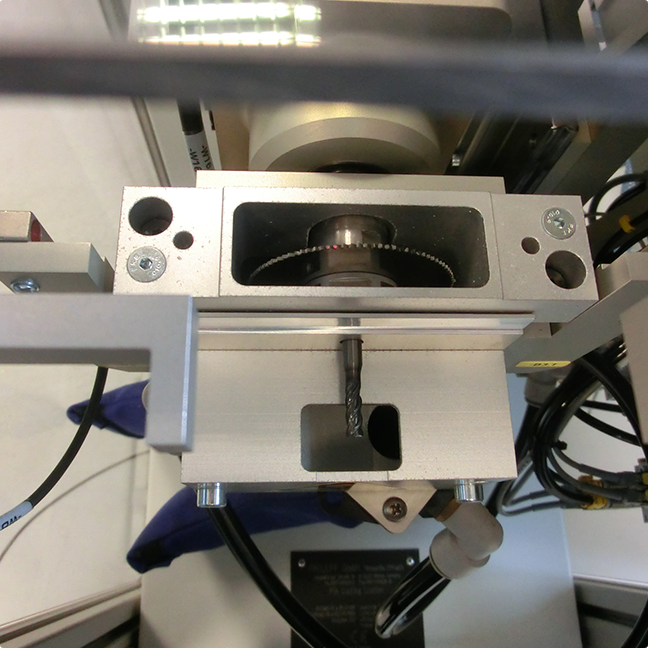

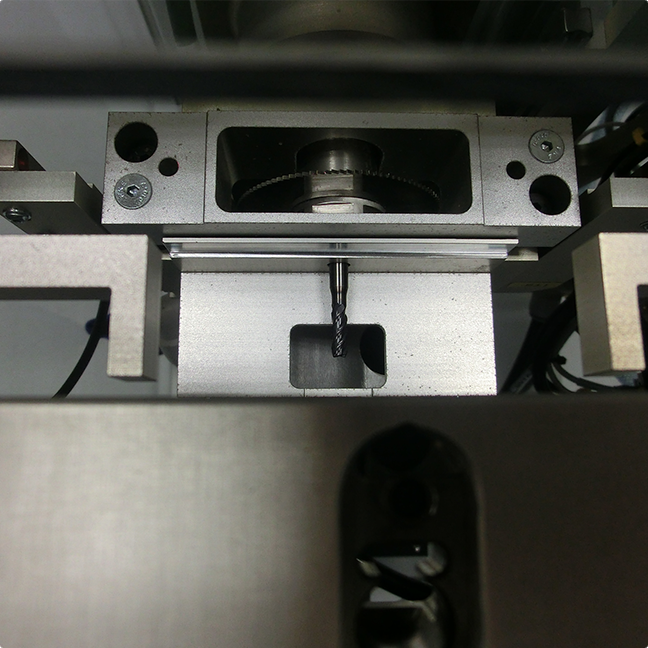

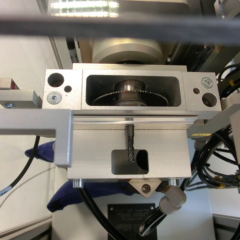

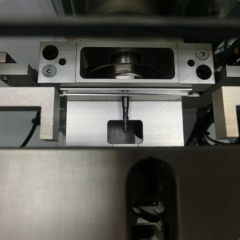

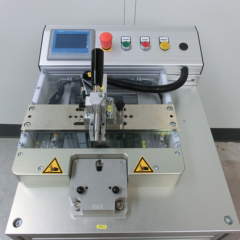

The pin cutter

Product-specific cross-cut device

The right cutWith the chip carrier systems, wheel speed sensors, so-called Hall sensors, are inserted fully automatically into the carriers provided for this purpose.

On these systems, it is possible to assemble the chips straight (= 180 degrees) or to bring the chip into the required geometry (90 degrees/120 degrees) fully automatically using an integrated robot.

The main components are

- Identification of the various materials using a barcode system

- Automatic feeding system for chips and carriers

- Punching out the carriers with disposal of the punching waste

- Automatic removal of the chip from the blister with a vacuum system

- Magnetic field measurement on the chip

- IO/NIO verification

- Feeding and processing of the chip by linear or robot units

- Mounting and latching the chip in the carrier

We are here for you!

Do you have any questions or requests?

Juan Bellver GarciaSales management