Our

Eddy current testing systems

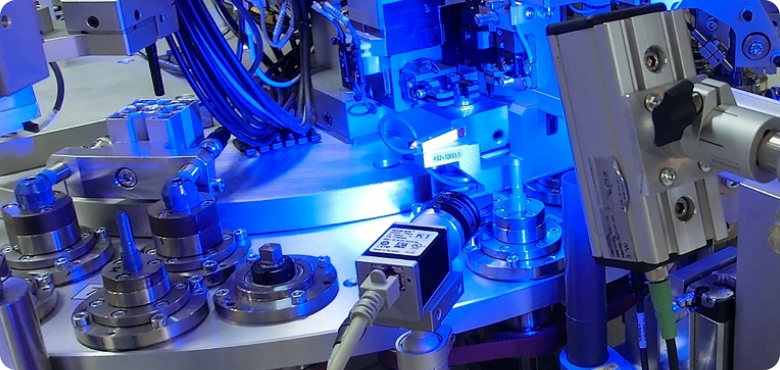

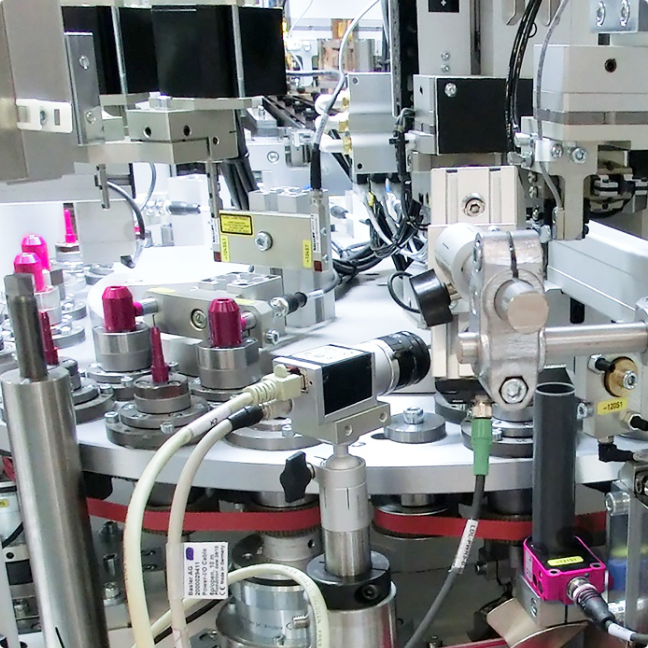

Maximum precision in all partsThe microstructure of precision deep-drawn parts is checked fully automatically on the inside and outside for cracks or material defects on our systems. This is a dynamic test with a high throughput and maximum precision. Tolerances of < 0.01 mm in the axial and radial area play a major role here.

The systems are divided into individual stations that can be customized to the customer’s requirements.

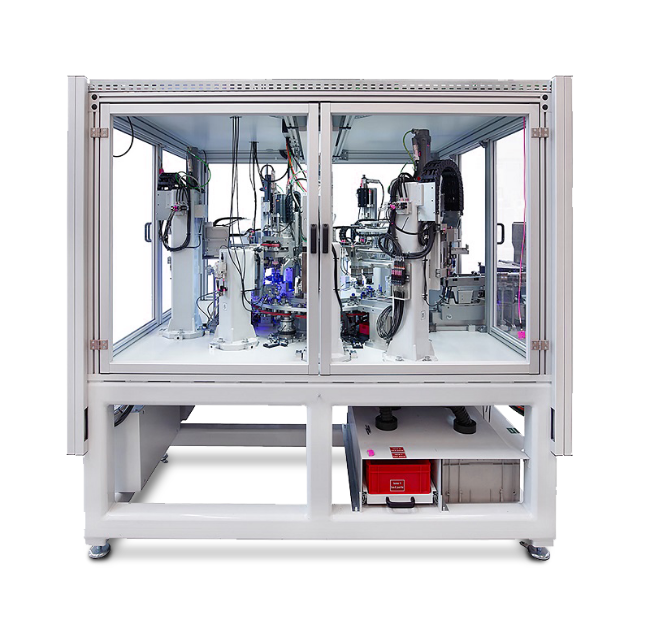

A typical layout includes the single or multi-track infeed with parts hopper, highly sensitive sensor technology for detecting the position of the component, various testing and turning stations as well as the ejection with 100% verification of IO and NOK parts. Other components include a vibration-neutral base frame, an ergonomic safety housing, a touch panel with intuitive menu navigation and a visualization of the system with its individual stations.

We are here for you!

Do you have any questions or requests?